Object Surface Defect Analysis

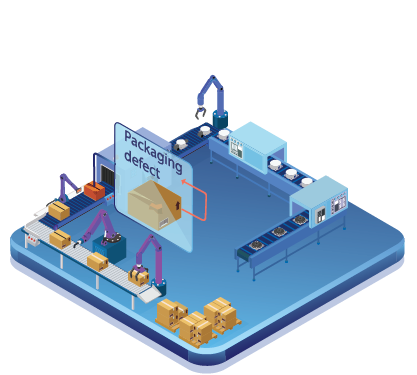

We at A for Analytics came out with a solution for carrying out defect analysis using AI that focuses on image annotation that filters out defective regions in any object by proper labelling.

Artificial Intelligence

Object Surface Defect Analysis

Surface defect detection using deep learning

In the manufacturing industry, knowing the ground level of errors at their early stage would help to rectify them early and also avoid huge defect occurrences in production. Finding out the defects manually is a herculean task, and it consumes more time, deploying the right technology, at the right place would be the cure.

Why choose our object surface defect analysis services?

Our object surface defect analysis services primarily focus on finding any defective object and denoting it to the concerned technician. Team A for Analytics deploys high-end deep learning models and techniques on the image annotation process that helps in identifying and labelling the defects on any object easily. By availing our service, manufacturing units can get rid of these defects at an early stage.

Carrying out defect analysis using AI reduces the chances of creating faulty products, and also ensures all the involved objects are of high quality and good condition. Apart from quality, it improves in increased production. The end goal of any manufacturing unit or company would be to attain maximum profit and using our surface defect detection using deep learning it can be achieved by any manufacturing adapter with ease.

A for Analytics has a dedicated team of professionals, who hold strong knowledge and immense experience in providing customized analytical solutions, and we as a team provide the best object surface defect analysis solutions that help in detecting and correcting incorrect objects with the assistance of image annotation.